I decided that I need a footstool. Not that I have a lot of time for putting my feet up, but I at least want the option. With that decision made, I moved on to design.

I decided that I need a footstool. Not that I have a lot of time for putting my feet up, but I at least want the option. With that decision made, I moved on to design.

The lowly footstool has existed in just about every shape and form that can be imagined. Not that the footstool has been the focus of designers throughout the ages, but that it has been a piece ubiquitous furnishing. No matter the time period or the economic status, everyone seems to have need of a footstool. This gives me an almost endless array of choices. So naturally I came up with my own version. Well, loosely based upon this photo of a mid-century version.

The lowly footstool has existed in just about every shape and form that can be imagined. Not that the footstool has been the focus of designers throughout the ages, but that it has been a piece ubiquitous furnishing. No matter the time period or the economic status, everyone seems to have need of a footstool. This gives me an almost endless array of choices. So naturally I came up with my own version. Well, loosely based upon this photo of a mid-century version.

Over the years I have amassed an eclectic collection of projects. There are a few traditional, several Japanese influenced and recently a few of the “staked” style. The trick has been to get them all to coexist as an ensemble. Material selection plays a big role. Mostly pine, oak and a smattering of other hardwoods. What really pulls the pieces together is my “decorative” elements. Wood burning, knot tieing and kolrosing can be found in varying degrees. The more pieces I build, the more effort I must put into ensuring that the aforementioned elements are incorporated to continue the semblance of a harmonious collection.

So, to design this little footstool I had a few goals in mind.

- Mid century modern flavor.

- Staked construction.

- Upholstered top.

- Fit on a 24″ square (I’ll explain).

- Proportional design.

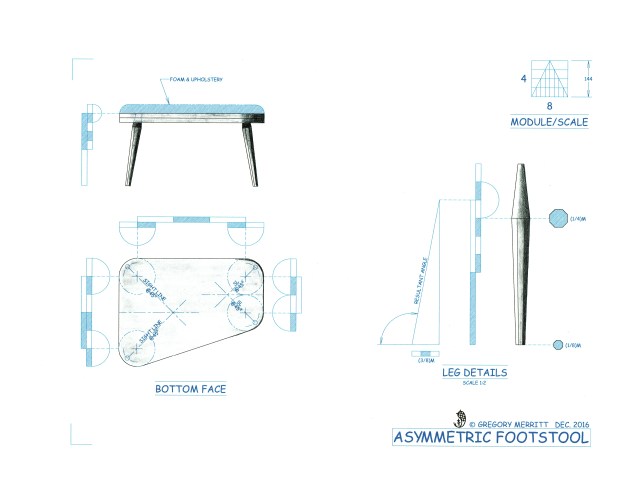

Th top will be asymmetrical. A simple layout with a compass and straight edge using a module based upon the desired height of the stool. After some trial and error I found a layout that fit within my 24″ square constraint.

WARNING: For the faint of heart purest who has stumbled upon this blog. I make full use of the Devil’s lumber (cheap plywood) in this project. Continue reading at your own risk!

I’m not sure how it is in the rest of the world, but here in the USA plywood is sold in 2ft square configurations. The big box home center sells 24″x24″, 24″x48″ and 48″x96″ sheets of ply. I wanted a thick top and I knew that I would need a double layer of ply. So a piece of 24″x48″ ply would yield a double layer lamination 24″ square.

- Pure design would not consider material thicknesses and sizes.

- Production design weighs the yield of multiple assemblies against available materials and overall cost.

- Hillbilly design works within the constraints of commonly available materials and strives to keep functionality, accessibility, cost and form in balance for single assemblies. 😉

This thick top would add rigidity and durability to the staked construction. It would also add weight to anchor the footstool in place. There is nothing worse than a footstool that you have to constantly chase and return to the desired location. Lastly, a thick stop adds strength and durability. This footstool will mostly be used as intended, but will also be pressed into service for sitting and even standing on (we have all done this). So I want it to be rock solid. The top will also be upholstered for comfort.

The legs will be the same as for my other staked pieces, oak. When I ordered oak billets for the side tables I ordered two extra blanks in case something went wrong. Those two pieces of 1-1/2″ oak will provide enough material for the four required legs.

So I have a design…

…and materials.

I’ll go into more detail concerning the design and get the making started in Part 2.

Greg Merritt Part 2

As always I love your drawings, this is going to be a good project. I’ve never seen a foot stool of this design shape before it’s unique, it resembles very much a retro 70’s design. I remember this kind of furniture as a child.

Thanks Salko! That is exactly what I intended…a retro look. Plus it will be nice to have something besides squares and rectangles. The construction is simple, but rock solid. Unless I make a mess of it of course. LOL

Seems like your recent experiences with staked furn and upholstering will serve you well in this one. Have fun with it.

Thanks Matt…I plan to…I really do enjoy the staked furniture process.

Those drawings are just beautiful. Pushing your boundaries, as always.

In my corner of the world, plywood is unanimously sold as 48″x96″, or to be exact, the metric equivalent which is a few millimeters wider (2440x1220mm) – quite unwieldy. Never saw any other size for sale…

Thanks so much! The plywood information is good to know. I am surprised that smaller sections are not made readily available to the public. Will the vendor at least cut the full sheet into smaller more manageable sections? Is delivery a common option for you?

Beyond my personal needs/wants, I try to make my projects in such a way that everyone, no matter their location, can easily replicate them. Material accessibility/availability is always the limiting factor.

“Devil’s lumber…” and “Hillbilly design…” great, just great!

How about “feedback” on the skateboard after some abuse – I imagine its been abused by now 🙂 🙂

Just trying to have a little fin with it. Hope it brought a smile to your face Antonio.

The report from my nephew is that the new longboard is “awesome”. He has even had a few offers from others wanting to buy it. He also says that he is already designing the next one. 🙂

From an old man (getting older by the day). Greg, I use a reclines-a-little Morris chair that came with a foot stool. I put my lap woodcarving doo-hickey-ma-bob on the foot stool now and keep my feet on the floor. My back doesn’t feel good, but it feels better this way. Be careful, young man.

Regards,

Jeff

Jeffrey L. Polaski 3007 Midvale Avenue Philadelphia, PA 19129-1027 jlpolaski@gmail.com 215-438-7855

On Sun, Dec 11, 2016 at 4:46 PM, HILLBILLY DAIKU wrote:

> Greg Merritt posted: “I decided that I need a footstool. Not that I have > a lot of time for putting my feet up, but I at least want the option. With > that decision made, I moved on to design. The lowly footstool has existed > in just about every shape and form that can be ima” >

I hear ya’ Jeff. My back and I have been on the outs since my late teens (compressed disk, paralyzed for a few hours, long story). Ironically, things that would destroy a healthy back actually make mine feel a little better. Conversely, my back can drop me to me knees for no good reason at any given time. 😉

No doubts solid wood is the first choice for long lasting projects. There are things worst then plywood IMHO: MDF, particle boards, osb, cardboard honeycomb, …

Look at Matthias Wandel site:

https://woodgears.ca/table/testing.html

Sylvain

Absolutely! MDF, partial board, osb, ect. should never be considered for furniture work. I have been doing some reading on plywood, it has a surprisingly long history in the furniture industry (mid 1800’s). I firmly believe that plywood, the correct plywood, has a place in the woodshop. Not just for jigs and fixtures.

I watched that video. WOW! It is amazing what is being produced and sold as furniture. That thing was basically just cardboard and glue!

Hey Greg, do your bad self a favour and try out the hard edge vs a softened edge on the top and how to upholster using foam, battling etc. The foot stool i made a few years back i took the hard corner off with a plane but i wish i would have padded better around the perimeter. (Over 3/4″ ply) all depends what you want, but a I still find that edge on mine ‘sharp’ sometimes. Looking forward to following your build.

Way ahead of you Brian. All edges, top and bottom, have a ~3/8″ radius. Then I’ll wrap the top in batting before installing the foam. I know that my foot will be pressed on the edge of this stool at least half of the time. A soft edge will be more comfortable and increase the life of the upholstery material. Thanks for the the input, I appreciate it.

Pingback: Asymmetric Footstool-Part 2 | HILLBILLY DAIKU

Pingback: Asymmetric Footstool-Part 3-Complete | HILLBILLY DAIKU