Frome left to right. Four crowns and a wall knot, tack knot with wall knot neck, star knot with wall knot neck.

I can almost hear you screaming at me through the internet, “What’s with all the knot tying!?”. So I thought I had better create this post so that you can better understand where I’m heading with all the knots that I have been posting about.

There is a long tradition of making your own hardware. Early craftspersons probably created knobs and pulls out of necessity. Then the blacksmith and silversmith came along and began forging and crafting hardware that could be purchased. The shakers took knob making to an art form in their time, crafting elegant knobs on the lathe. More recently James Krenov, Paul Sellers and others have advocated crafting knobs and pulls in the shop.

Lets face it, we no longer need to create our own hardware, we can purchase just about any style we want. So why go to the trouble. I believe that by creating some of our own hardware we can put our own unique stamp on the things that we create. More over, hardware can be expensive.

Since one of my hobbies is knot tying, I quickly became aware of how sailors of the past crafted knobs and pulls to outfit ships interiors as well as their sea chests. So I took that information and developed a few simple knobs that I think are quite nice and can be created out of just a few pieces of twine. You can stock up on quite a bit of hardware while watching TV in the evenings and you will have them at the ready when the time comes.

That is why I’m posting about knots. I felt that the best way to show you how to create these knobs was to show you the basic knots that will be combined to create them. Hopefully, that will make it much easier for you to create your own knobs. By altering the size, number or type of twine used you can create a wide variety of knobs and pulls lending an element of uniqueness to your projects. Very soon I’ll be posting the instructions for making the knobs I have pictured here. These are just a few of the possibilities. I hope that you give them a try.

Greg Merritt

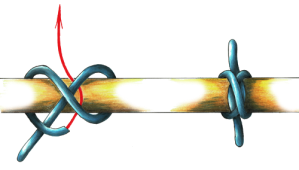

The wall knot is the reverse of the crown knot. Like the crown knot, the wall knot is of limited use by itself. However, when used is combination with other knots, the wall knot is the basis for a number of practical and decorative knots. I have shown the knot tied with three strands but it can be tied in any multiple number of strands. I find that three strands are ideal for learning this knot.

The wall knot is the reverse of the crown knot. Like the crown knot, the wall knot is of limited use by itself. However, when used is combination with other knots, the wall knot is the basis for a number of practical and decorative knots. I have shown the knot tied with three strands but it can be tied in any multiple number of strands. I find that three strands are ideal for learning this knot. The crown knot, in and of itself it has very little use. So why did I go to all of the trouble of creating an instructional drawing and writing this post? The crown knot, along with the soon to be introduced wall knot, is the basis for a number of practical and decorative knots. I have shown the knot tied with three strands but it can be tied in any multiple number of strands. I find that three strands are ideal for learning this knot.

The crown knot, in and of itself it has very little use. So why did I go to all of the trouble of creating an instructional drawing and writing this post? The crown knot, along with the soon to be introduced wall knot, is the basis for a number of practical and decorative knots. I have shown the knot tied with three strands but it can be tied in any multiple number of strands. I find that three strands are ideal for learning this knot.

The

The